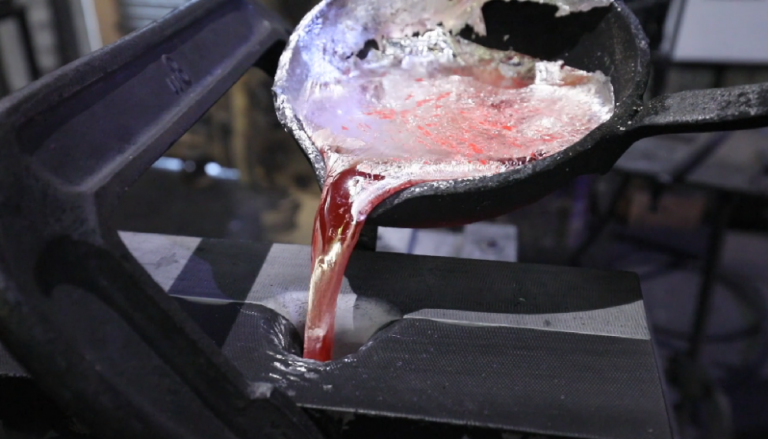

If you are familar with aluminum parts, you may also be interested in the forming processes of them, mainly including casting, forging and machining. Casting is a process that allows foundries to create products with complex shapes while light weight. The process begins by creating molds. Then, workers pouring melton aluminum alloy into molds to achieve desired shape.

Benefits of Aluminum Casting Process

Only Aluminum Casting Can Produce Intricately Designed Parts

One of the best reasons why a wide variety of industries and consumers choose aluminum casting is the fact that it allows the manufacturer to produce aluminum parts that have intricate designs. In other words, it’s possible for them to order customized aluminum castings that perfectly suit their production needs.

The Production Process of Aluminum Casting is Faster than Machining

With aluminum casting, you’ll be able to produce parts faster than machining process? Since it allows you to create near-net shapes, you can easily eliminate the process of machining to get your desired results. This implies that with aluminum casting, you’ll be able to produce the finished parts much sooner than you initially expected.

Aluminum Casting is Very Affordable

If you want to obtain top-quality metal products at a much cheaper price, choose aluminum casting process. Since this kind of manufacturing process require less machining, the unit cost is considerably lower compared to other alternatives.

Aluminum Castings are as Strong as Steel Castings

Despite being weighing very little, aluminum castings features the same strength as that of steel castings. Thanks to its superior metallurgical properties, aluminum castings exhibit a higher degree of pressure tightness. In fact, their strength advantage is evident over sand castings and other options.

When is Aluminum Casting Applied?

Manufacturers often use aluminum casting when forging or machining of aluminum alloys cannot be employed. This material that comes with a luminous finish is used in producing different commercial and household goods. To give you an idea about when aluminum casting can be used, below we list out some typical applications of cast aluminum parts:

Construction and Architecture

Since aluminum is known for its outstanding conductivity and its light weight that works well for extended lengths of cable runs, copper has now been replaced by aluminum as the base for electrical transmission lines and power grids. Furthermore, architects use aluminum castings for renovations that include ornamental door framings, rooftop corner pieces, and reinforcement pieces.

Aerospace

Since the combination of aluminum castings’ properties including its light weight and strength make them ideal for the development of vehicles that are both strong and light enough to go beyond the earth’s atmosphere, the aerospace industry has been greatly dependent on them. In fact, commercial transport planes are comprised of 80% aluminum castings. Plus, aluminum is extensively used in the space industry for shuttles as well as for various structures at the international space station.

Appliance and Technology

Aluminum castings are also used for refrigeration applications primarily because of its thermal properties and its light weight that allow easy transport.

Renovation and Restoration

In most cases, restoration projects can present unique challenges because they can be quite difficult to source designs that match the metal elements that need to be replaced. It doesn’t matter if the existing casting needs to be directly copied or a new master pattern needs to be carved – aluminum castings will be perfect for duplicating hard-to-find castings that can help you finish the historical restoration with the components that you need.

Want Investment Casting for your Next Project?

If you are interested in using aluminum gravity die casting or aluminum pressure die casting for your next project, contact TCC Casting!