Why Choose Small hard alloy pad Welding Technology in Decanter Centrifuges?

Comparison of Wear-Resistant Technologies Among Major Brands

| Brand | Gasket Welding | Alternative Technology | Application Areas |

|---|---|---|---|

| ANDRITZ | ✅ Yes | Small tungsten carbide gaskets | Municipal, Biomass, Chemical |

| Flottweg | ✅ Yes (some models) | Replaceable liner + welded gasket modules | Hazardous waste, Mineral processing |

| Alfa Laval | ❌ No | Zirconia ceramic covering | Food, Marine, Mining |

| Westfalia | ❌ No | Ceramic coating, Alloy inlay | Pharmaceuticals, Fine chemicals |

| Pierre Reis | ❌ No | Carbide spraying + Alloy spiral | Mining, Oil drilling |

Key Benefits of Small Wear-Resistant Pads

The spiral blades in decanter centrifuges are exposed to intensive abrasive wear due to continuous contact with solid particles such as:

- Mineral fines

- Crystalline salts

- Biomass residues

- Metal fragments

Welding small carbide pads to the screw conveyor blades addresses these issues effectively.

Advantages Include:

- ✅ Superior Abrasion Resistance: Protects against high-hardness materials in contact zones.

- ✅ Reduced Maintenance: Sacrificial pads absorb wear, protecting the main spiral blade.

- ✅ Extended Equipment Life: Delays the need for expensive part replacements.

- ✅ Lower Downtime: Minimizes operational interruptions due to wear-related failures.

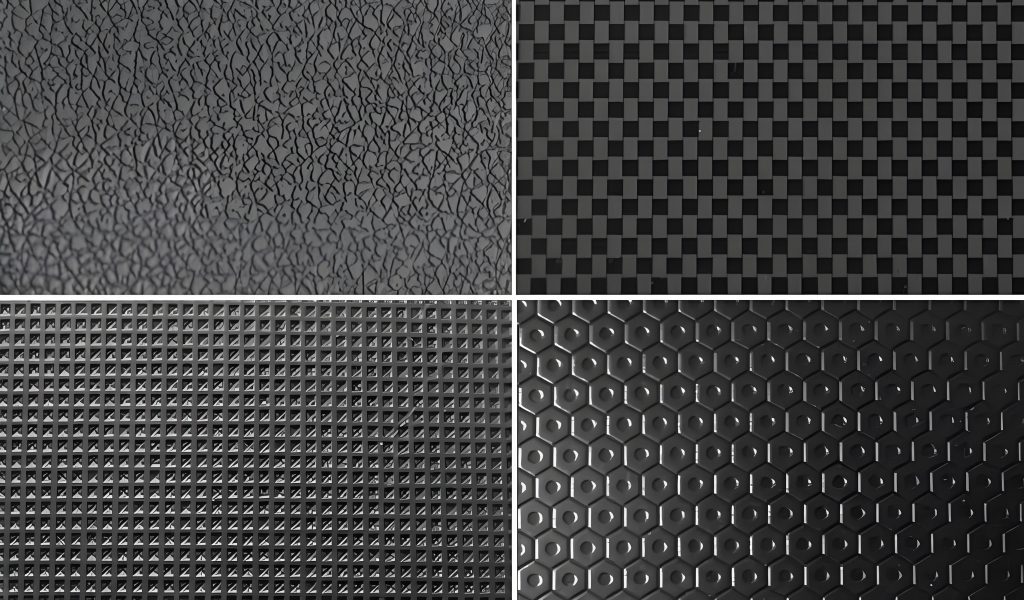

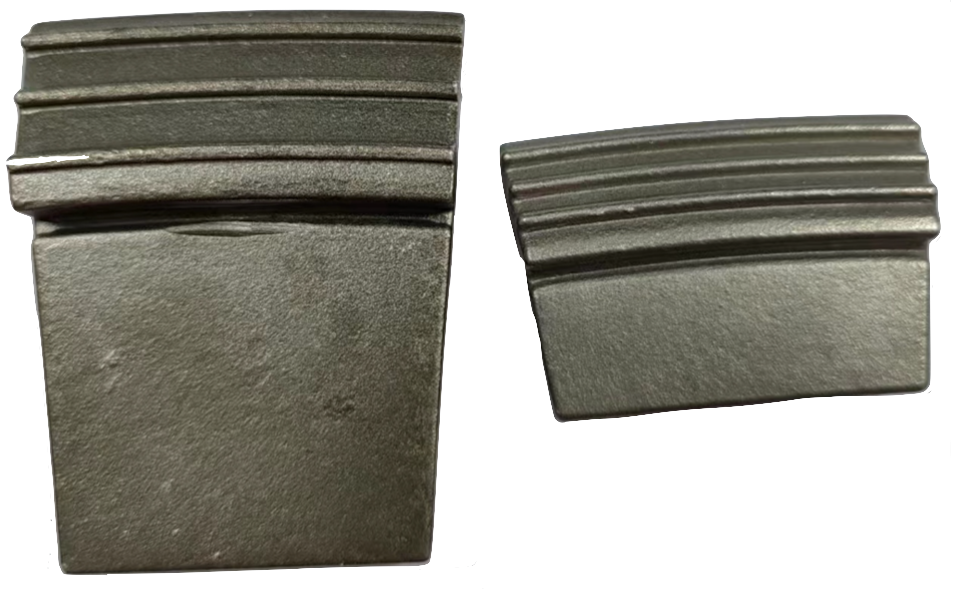

Why Weld Multiple Small Gaskets Instead of One Large Plate?

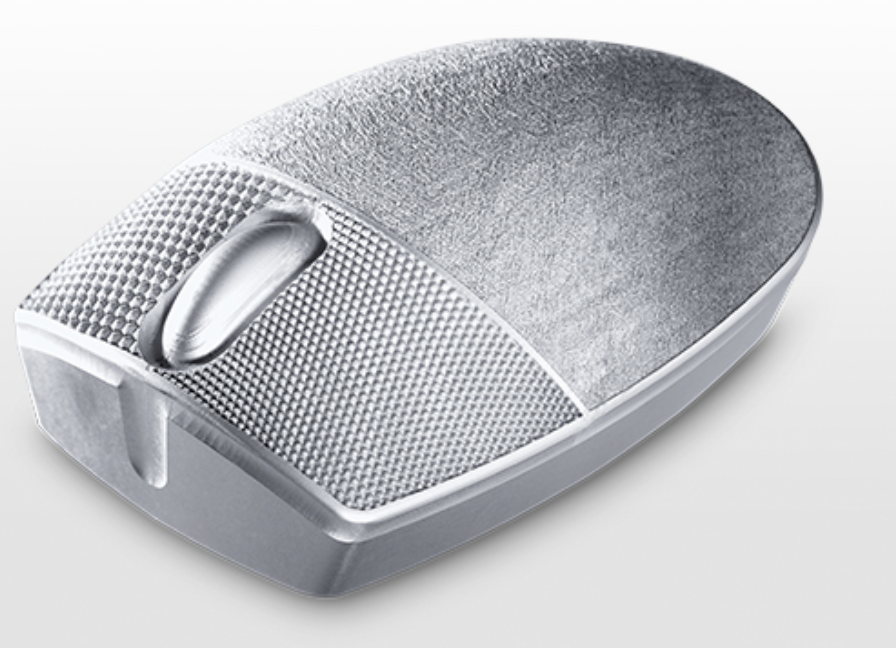

- Adapts to Complex Curved Surfaces: Easier installation on helical blade geometries.

- Distributes Stress & Impact: Reduces crack risk due to thermal/mechanical stress.

- Simplified Maintenance: Damaged gaskets can be selectively replaced.

- Enhanced Welding Quality: Smaller weld zones improve structural integrity.

- Cost-Effective Over Time: More targeted protection with reduced material waste.

Case Studies: Brands Utilizing Gasket Welding

ANDRITZ

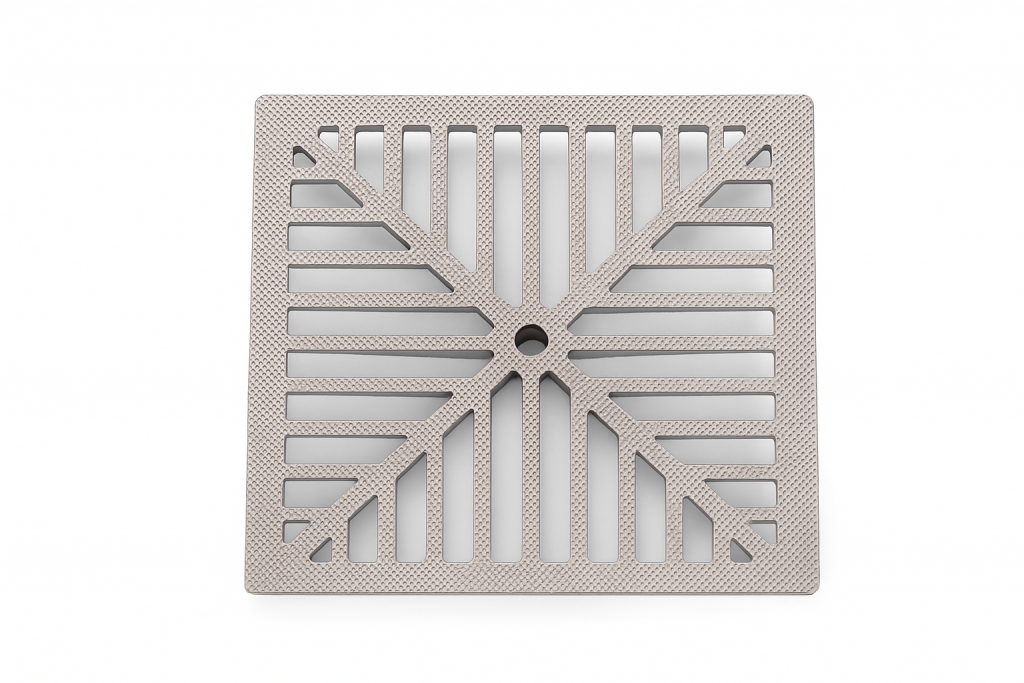

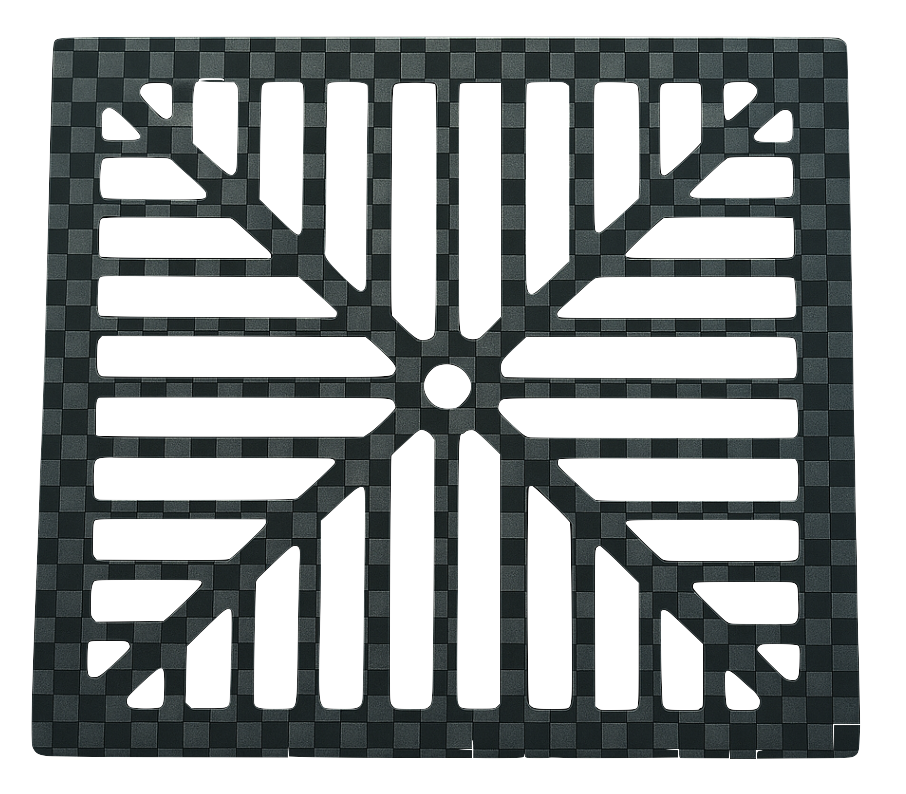

- Technology: Dense welding of small tungsten carbide gaskets (10–20 mm) on blade surfaces.

- Advantages: Excellent coverage of high-wear areas, replaceable modules, strong substrate bonding.

- Use Cases: Municipal sludge, biomass waste, chemical sludge.

Flottweg

- Technology: Modular wear liners with welded carbide blocks or strips.

- Advantages: Dual protection (liner + gasket), high replacement efficiency.

- Use Cases: Hazardous industrial waste, mineral tailings.

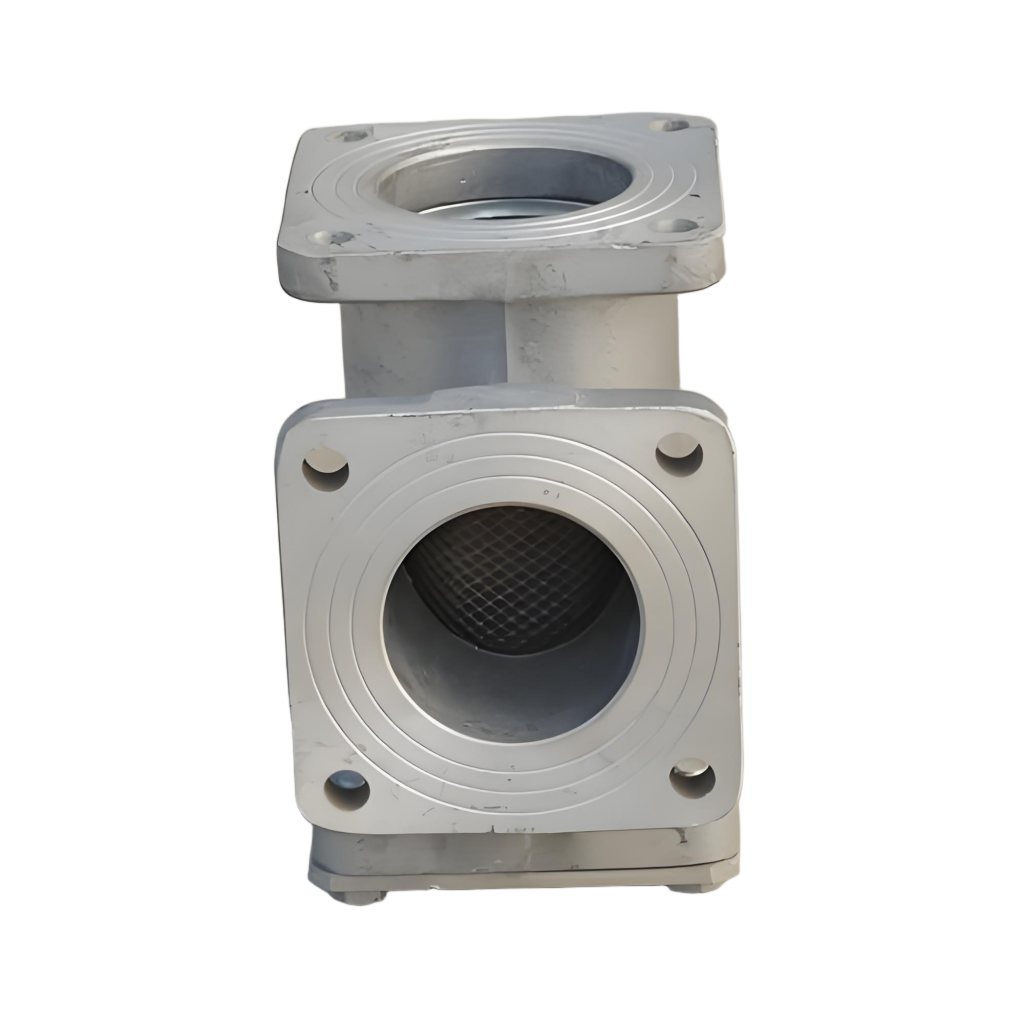

TCC’s Contribution: Custom Casting & Welding of Carbide Gaskets

TCC Co., Ltd specializes in producing high-quality cast carbide gaskets, supporting welding services with strong material compatibility.

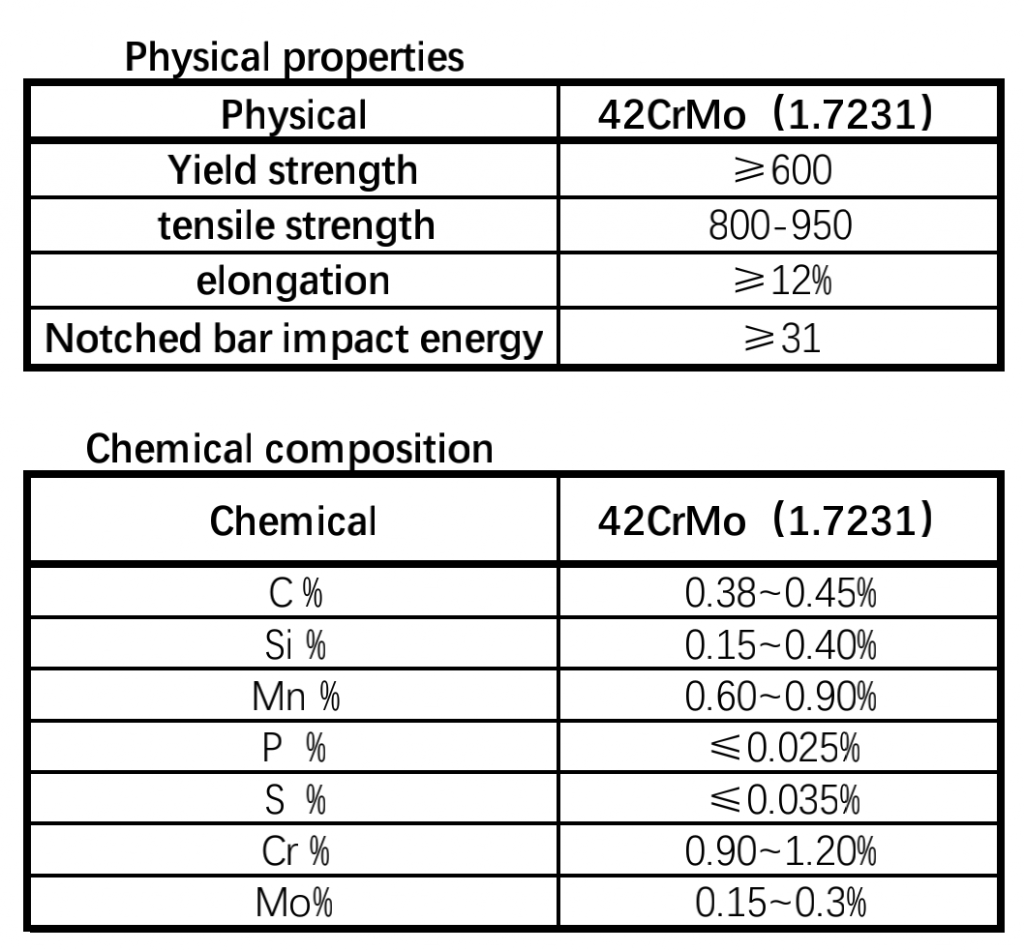

Materials Commonly Used:

| Material | Key Feature | Typical Application |

|---|---|---|

| Tungsten Carbide (WC-Co) | Ultra-hard, durable | Mineral wear, solids processing |

| Chromium Carbide (Cr₃C₂) | Corrosion-resistant | Chemical and biomass slurry |

| NiCr-Si-B Alloys | Weldability, thermal match | Stainless steel blades, uniform stress |

| Cermet | Thermal shock resistance | High-temp drying, crystallization |

Advantages of Cast VS Machined Gaskets

- Complex Shapes in One Step: Cast gaskets fit curved surfaces more naturally.

- Material Gradient Design: Can embed cores with different thermal/mechanical properties.

- Scalable Cost: Casting becomes economical for high-volume, high-alloy content parts.

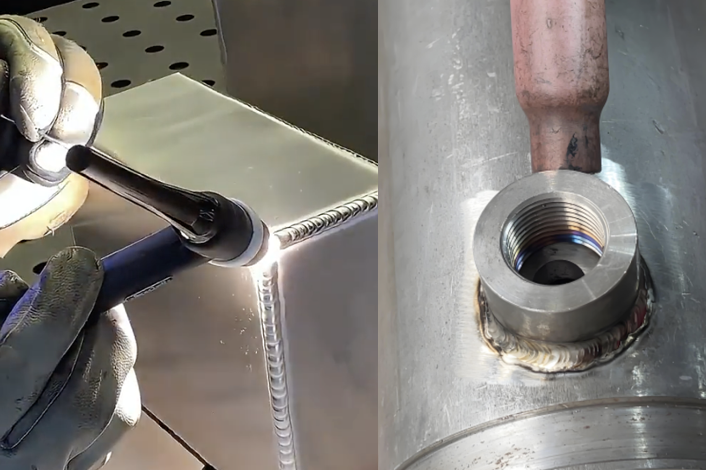

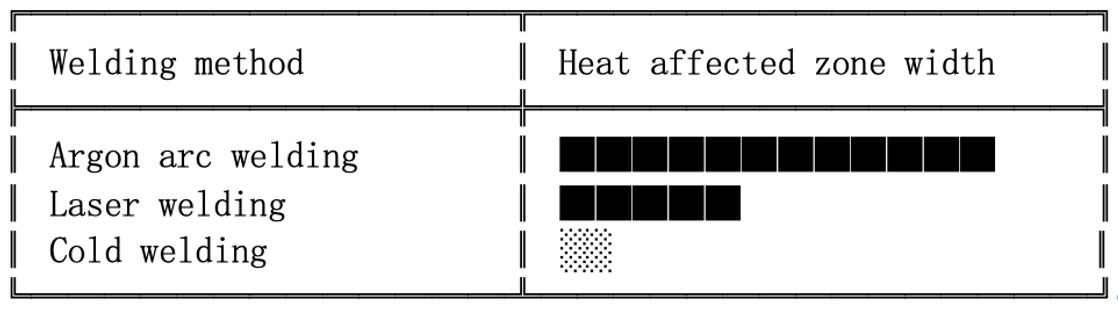

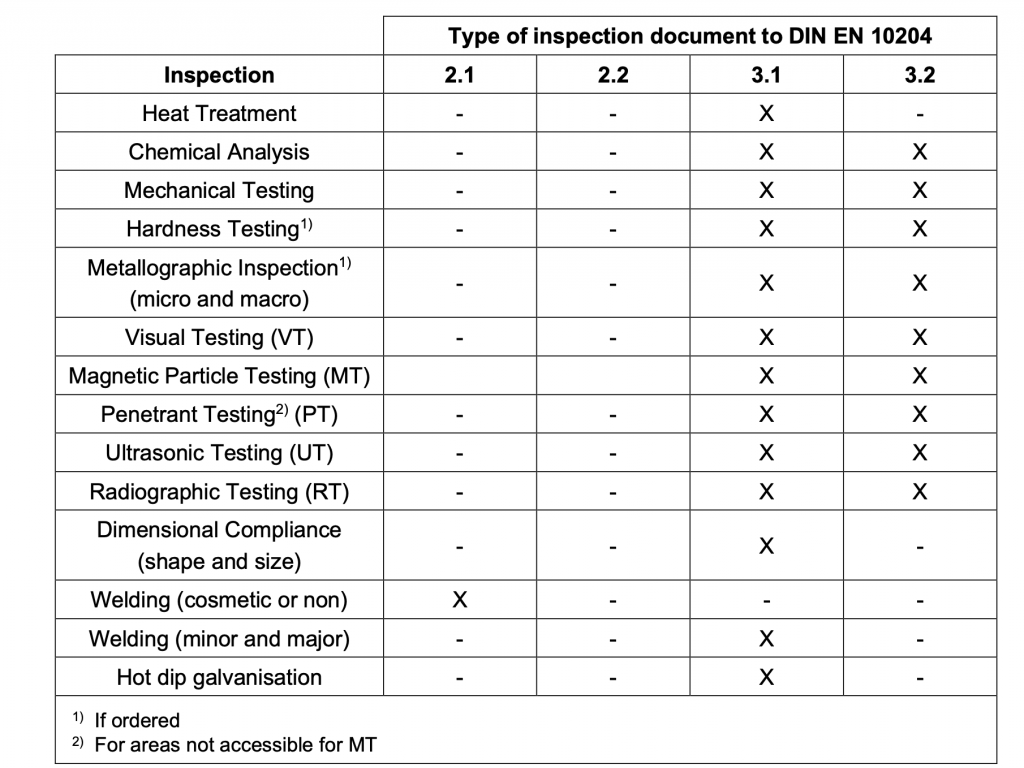

Welding Methods and Process Control

Common Welding Techniques:

- Brazing: For low-stress or smaller parts; uses Ni or Ag-based filler.

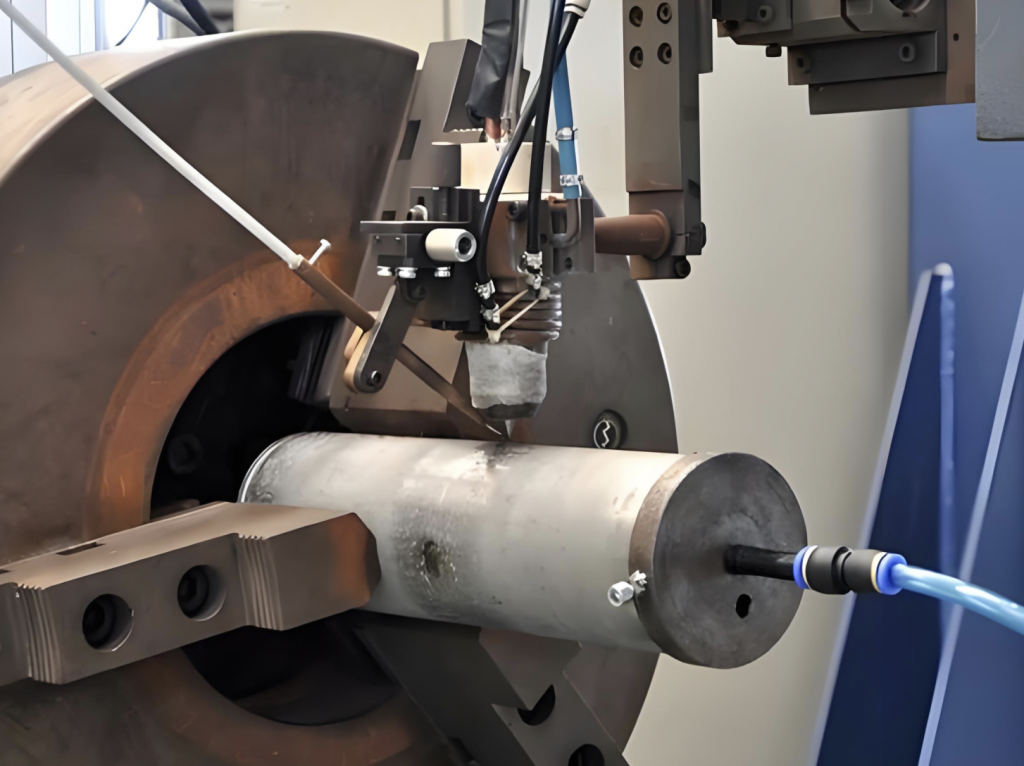

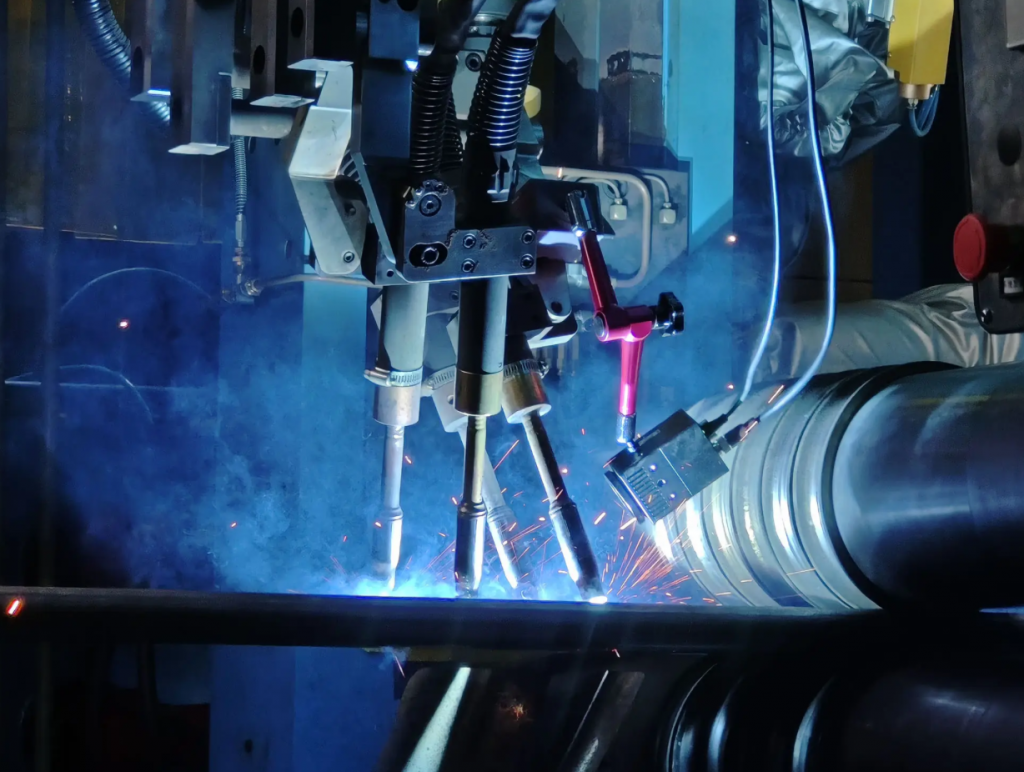

- Plasma Arc / Laser Welding: Precision, low distortion, ideal for thin blades.

- Surfacing + Composite Welding: For enhanced impact and wear performance.

Process Control Tips:

- Preheat and slow cooling to reduce cracking risk.

- Maintain strong fusion and proper weld penetration.

- Use staggered multi-point welding to minimize distortion.

Industry Trends

- 📌 Standardized modular gasket systems are gaining popularity.

- 🤖 Asian manufacturers have adopted automated gasket welding machines.

- 🔍 Smart monitoring systems now provide wear tracking and replacement recommendations.

Conclusion

The welding of small wear-resistant carbide pads onto decanter centrifuge spiral blades is a technically efficient, cost-effective, and scalable solution for industries facing harsh abrasive environments. TCC offers robust capabilities in casting, material matching, and welding—making it a reliable partner in extending the life and performance of high-value rotating equipment.