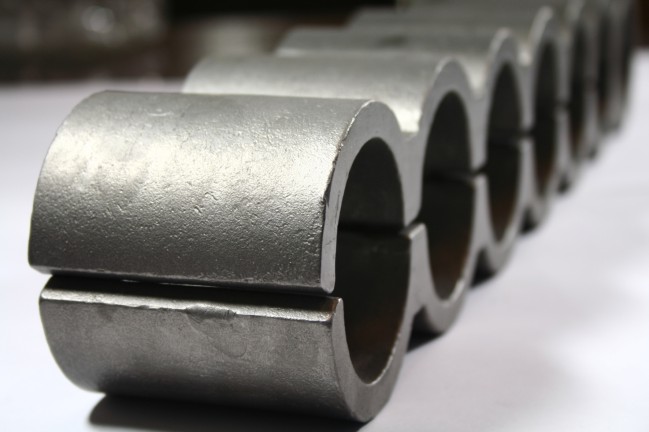

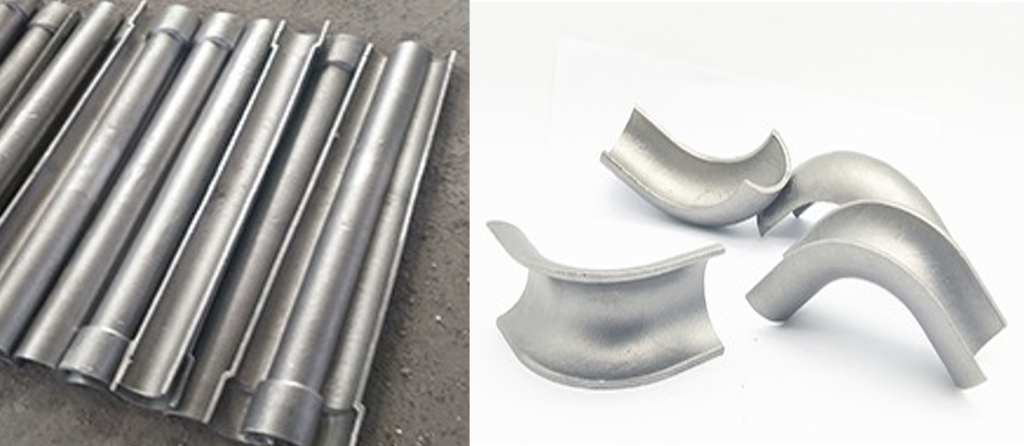

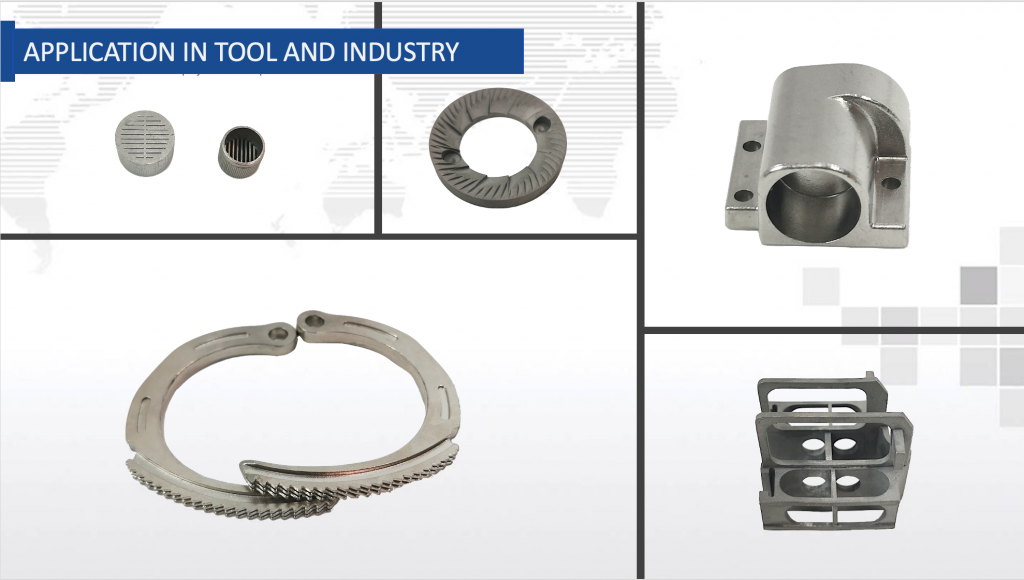

In TCC Casting, our aluminum gravity die casting technique can make quality cast aluminum parts for a range of industries, including Marine, Cars & Trucks, Gas Turbines, Compressors, Pumps, Valves, Medical Equipment, etc.

What is Gravity Die Casting?

Gravity die casting, may also called as permanent mould casting, is a typical die casting technique to creat high quality metal components which have low melting points, such as aluminum and zinc alloys. In gravity die casting process, the molten metal is poured from a ladle into the mould, then fills the mould cavity under the force of gravity and fastly solidified to achieve metal parts. This process gives a better surface finish than sand casting as well as better mechanical properties, both due to rapid solidification.

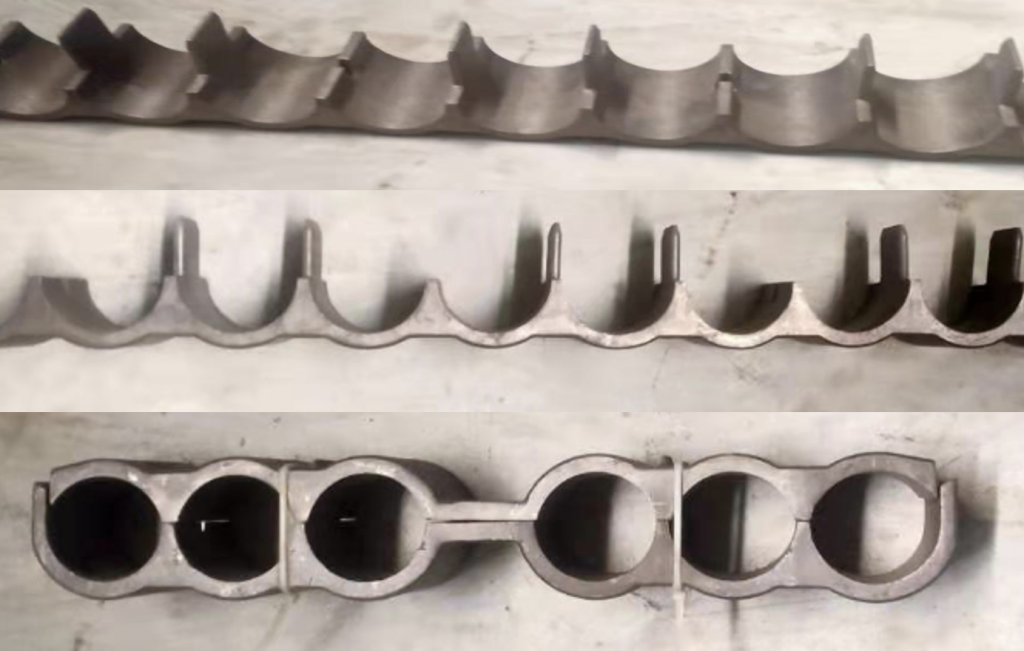

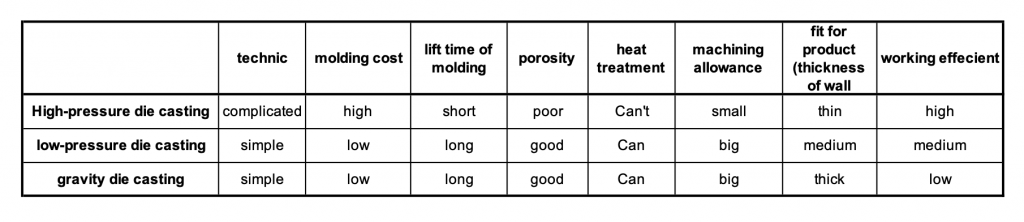

Unlike other casting methods, gravity die casting is a simple pouring of the molten metal into the mould without any additional pressure applied. And, gravity die casting can use both metal and sand cores, referred to as semi-permanent mould casting, for greater complexity of design. It is the perfect choice for applications that require a solution that’s somewhere in between sand casting and high-pressure die casting. Gravity die casting requires lower mould cost than high pressure die casting, but more durable than sand casting by using a steel mould. The mould is a permanent form that consists of two halves.

Gravity Die Casting Process

Gravity die casting is often a manual process, with the molten metal added with the use of a ladle. However, for some high volume applications it is also possible to use an automated ladle to pour the molten metal. The speed and the direction of the filling can also be controlled by tilting the die.

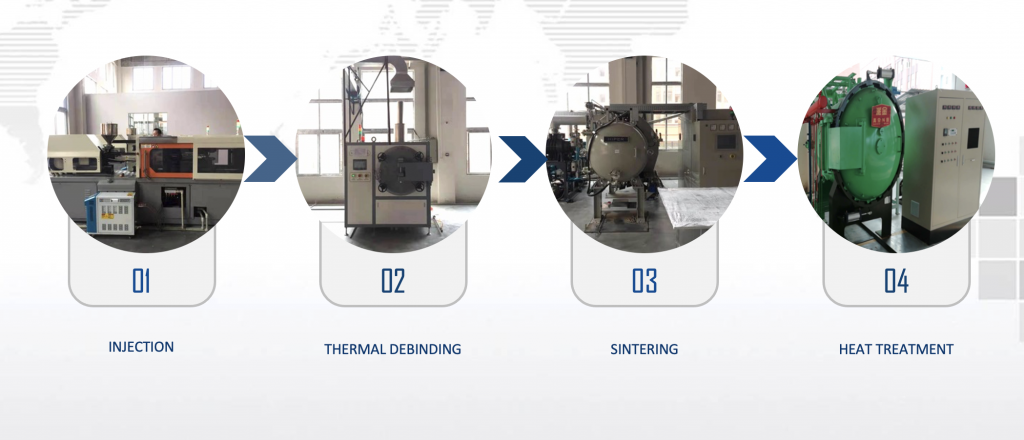

Apart from the method by which the molten metal is poured into the die cavity, and the gravity die material, the casting process is essentially the same as sand casting. It involves four steps:

- The die is heated and then sprayed with a refractory coating, and closed. The coating both helps control the temperature of the die during manufacture and it also assists in the removal of the casting.

- Molten metal is then manually poured into the die, (although in some cases a machine can be used) and allowed to solidify.

The die is then opened and the cast parts either removed by hand or in some cases ejector pins are used on the mechanised machines. - Finally, the scrap, which includes the gate, runners, sprues and flash, is removed from the casting(s). The castings are then processed to remove sharp edges and excess material, then blast cleaned (if required) prior to despatch to the customer.

- Gravity die casting is a natural partner to sand casting, and allows us to offer the customer the most cost effective route for casting manufacture.

Advantages of Gravity Die Casting Process

One of the advantages of gravity die casting process is that it can produce high quality castings with complex shapes, while still maintaining excellent mechanical properties like strength. That makes it very suitable for creat aluminum castings that can not be satisifed by pressure die casting process.

Gravity die casting advantages include:

- suitable for parts in both low and high-volumes.

- suitable for larger, thicker parts that can not be produce by pressure die casting process.

- less investment in mould compared with pressure die casting process.

- produces components with far smoother surfaces than that of sand casting method.

- produces parts with excellent mechanical properties, and T6 heat treatment can also be applied to improve the properties.

- almost no dimensions limitation and complex shapes can be realized. For products with hollow areas, sand cores can be placed into the mould.

Tips on Selecting Gravity Die Casting Process

It is very important to select a suitable casting process for your design. Before making a decision, several factors should be taken into consideration, such as process limitation, production effeciency, investment, dimensional accuracy, surface finish, lead time, etc. Normally, purchasing companies prefer to buy castings from China foundries like TCC casting, due to its mature production process and low production cost.

Sometimes, a designed part is suited to both gravity die casting and pressure die casting processes (differences between gravity die casting and pressure die casting). Gravity die casting is suggested when the order quantity is small because it has lower mould cost. Remember not all the metals can be cast by this process, only metals that have low melting points are suitable. But for thinner parts, pressure die casting process is considered as it is easy to occur defects if choosing gravity die casting process.